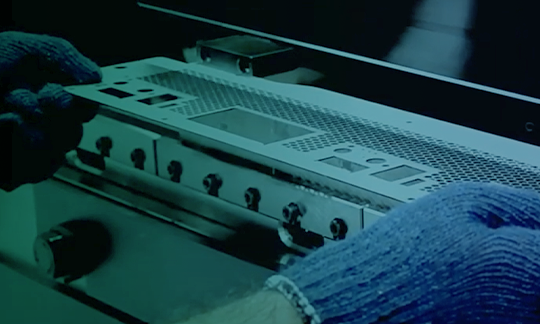

Manufacturing Low Cost, and High-Quality Precision Molded Plastics Parts

VVDN's cutting-edge Injection Molding Facility is dedicated to delivering top-quality plastic injection molded parts, no matter the size or complexity. With extensive experience in manufacturing plastic molded components, we serve a diverse range of industries, including Telecommunications, Security & Surveillance, Energy & Utility, Consumer Electronics, Industrial, Automotive, Medtech, Datacenters, and Networking.

We support our customers from initial prototyping through to high-volume injection molding production. With skilled operators and automated injection molding machines, we offer end-to-end manufacturing solutions. Our services cover all stages of the process, including raw material verification, tool making, part fabrication, finishing, and final inspection.