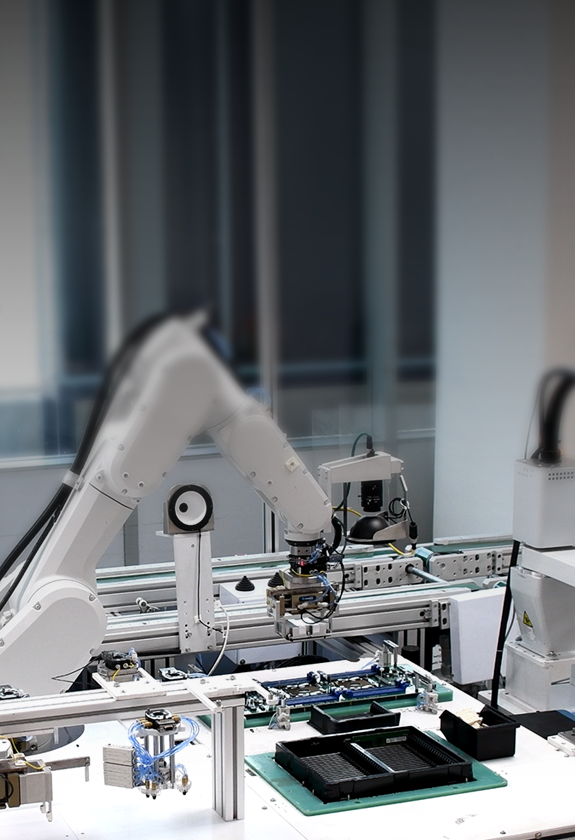

For high-volume product manufacturing, VVDN enables automation by developing and deploying custom SPMs that streamline and optimize product assembly. These machines automate complex and repetitive tasks, significantly improving production speed, assembly accuracy, and overall line efficiency. By integrating robotics, vision systems and smart handling mechanisms, we help manufacturers reduce manual labor and ensure consistent quality at scale.

Key capabilities include

- Gantry System (Path Interpolation): Precision placement of components like ICs on PCBs using multi-axis motion control.

- Robotic Soldering, Screwing & Locking: Ensures uniform fastening and secure electrical connections.

- Automated Inspection & Quality Checks: Vision and sensor systems for in-line defect detection at the PCBA level.

- Pick-and-Place Systems: High-speed and accurate placement of electronic and mechanical parts.

- Quality Assurance: AOI and interlock mechanisms to verify secure assembly and detect defects before packaging.

VVDN enables end-to-end automation of internal logistics, material flow, and warehouse operations by integrating intelligent robotics and smart control systems. From inventory movement to final dispatch, we develop and deploy automation solutions that improve efficiency, accuracy, and space utilization while reducing manual effort.

Key capabilities include

- Robotic Palletizing & Depalletizing: High-speed, safe stacking and unstacking of goods.

- Robotic Packaging Lines: Automated product pick-and-place into packaging for enhanced speed and precision.

- Automated Sorting & Routing: Vision or barcode-based material direction for efficient flow.

- AGVs & AMRs: Flexible mobile robots for dynamic intra-logistics and material movement.

- RFID/Barcode Inventory Scanning: Real-time tracking for accurate inventory management.