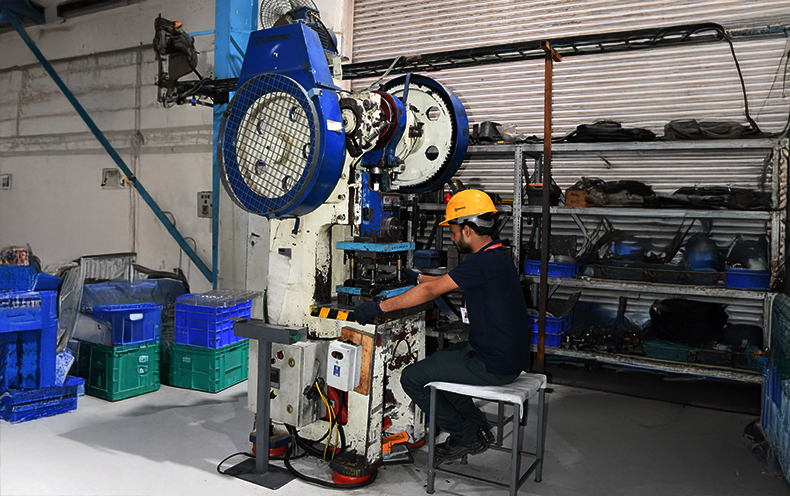

At VVDN, we offer end-to-end sheet metal fabrication solutions for OEMs, catering to a wide range of industries. From initial concept and precision design to advanced sheet metal fabrication processes—including laser cutting, punching, welding and high-quality paint finishing—we oversee every aspect of the fabrication journey with meticulous attention to detail. With deep expertise in designing and fabricating components such as enclosures, chassis, cabinets and other parts for the electronics industry, VVDN combines precision and efficiency to deliver solutions that meet the ever-evolving demands of modern manufacturing.