In today’s camera-driven world, image quality isn’t just a feature—it’s a necessity. Whether it’s a smartphone, a surveillance system, an automotive camera, or a smart vision device, the ability to deliver consistently sharp, distortion-free images defines product performance. One of the most critical yet often overlooked aspects of delivering that precision is active alignment.

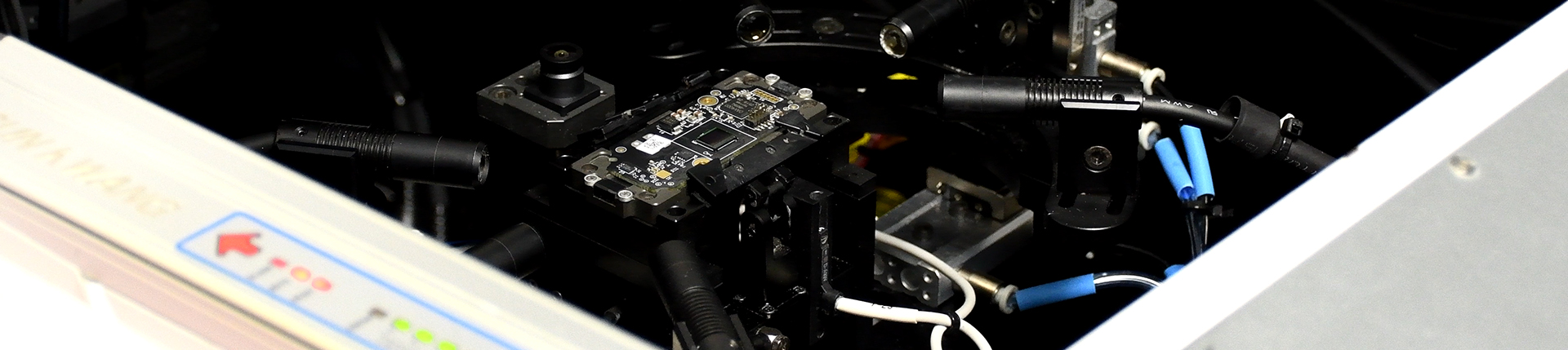

At VVDN Technologies, where we specialize in end-to-end camera design and manufacturing, active alignment plays a pivotal role in ensuring that each camera we produce meets the exacting standards of clarity, reliability, and performance.

Table of Contents

What Is Active Alignment?

Active alignment is the process of adjusting the lens and image sensor in real-time—while monitoring live image feedback—to achieve optimal focus and image quality across the entire sensor plane. Unlike passive alignment, which relies solely on mechanical fixtures and tolerances, active alignment uses real-time image analysis to fine-tune the alignment with sub-micron precision.

This process ensures that:

- The lens is perfectly centered over the image sensor

- The focus is optimized across the entire field of view

- Aberrations and distortions are minimized

- Optical performance is maximized (e.g., MTF, field flatness)

How the Active Alignment Process Works

Here’s a high-level view of the typical steps involved in active alignment at VVDN’s camera manufacturing lines:

- Module Pre-Assembly

The image sensor and the lens holder are permanently mounted on the PCB. A dedicated alignment fixture is used to hold and precisely position the lens within the lens holder during the active alignment process. - Live Image Capture

The module captures a live image of a high-precision test chart (e.g., Siemens star, slanted edges, or checkerboard patterns). - Multi-Axis Adjustment

The lens is moved in five or six degrees of freedom (X, Y, Z, tilt, tip, and sometimes rotation) using ultra-precise motorized stages. - Image Quality Optimization

Real-time algorithms continuously evaluate image quality metrics such as sharpness, MTF symmetry, contrast and edge response, and field flatness. The system iteratively adjusts the lens position until the best achievable optical performance is reached, maximizing usable image quality across the full field of view. - Fixation

Once alignment is optimized, the lens is fixed in place using UV-curable adhesive or laser welding. - Final Quality Verification

The fully aligned module undergoes final validation to confirm MTF compliance across field, Focus and tilt stability.

Where Active Alignment Makes the Biggest Impact

Active alignment is essential in industries where optical precision and product reliability are non-negotiable:

- Automotive ADAS Cameras

For lane detection, object tracking, and collision avoidance, precise focus and distortion-free images are critical. - Smartphones and Tablets

Ultra-compact modules require exact alignment to deliver high-resolution performance in small form factors. - AR/VR Devices

Depth sensing, eye-tracking, and immersive visuals depend heavily on perfect optical alignment. - Security & Surveillance Systems

Sharp and consistent imaging, even in edge regions of wide-angle lenses, enables better facial recognition and video analytics. - Industrial Machine Vision

In high-speed inspection systems, even minor misalignments can lead to false positives or missed defects.

VVDN’s Expertise in Active Alignment

At VVDN, we’ve invested in state-of-the-art automated camera assembly and active alignment systems across our manufacturing facilities. Our process includes:

- Robotic 6-DOF alignment platforms with image-based feedback

- Precision glue dispensing and UV curing systems

- Customized algorithms to evaluate MTF, centering, and distortion

- Cleanroom environments to maintain particle-free assembly

- Automated end-of-line testing integrated with MES systems

Why It Matters

With growing demand for smarter, smaller, and more capable camera systems, the margin for optical error has shrunk dramatically. Active alignment is no longer a luxury—it’s a requirement for brands that care about delivering professional-grade camera systems at scale.

Whether you’re building the next generation of automotive vision systems or AI-powered edge cameras, active alignment ensures that every pixel contributes to a sharper, smarter image.

Partner with VVDN for Precision Camera Design and Manufacturing

At VVDN, we don’t just build cameras—we engineer vision. From custom optics to complete camera modules, from PCB design to active alignment and automated EOL testing, our capabilities help OEMs and brands accelerate innovation without compromising on quality.

Let’s talk if your next vision product demands precision in every pixel.