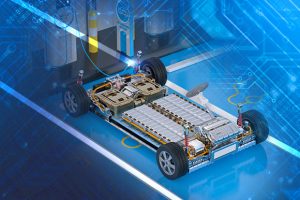

The electric vehicle market is charging ahead at an unprecedented pace, but its growth depends heavily on one factor — the reliability and safety of charging infrastructure. From home chargers to public fast-charging stations, from on-board vehicle chargers (OBCs) to wall-mounted AC units, every system must work flawlessly, regardless of brand, location, or climate.

For EV OEMs, aftermarket brands, and automotive manufacturers alike, comprehensive testing is no longer optional — it’s essential. A single charging failure — whether in an external charger or an OBC inside the vehicle — can erode user trust and delay market adoption. At VVDN Technologies, we help industry players validate their EV charging solutions against stringent performance, safety, and interoperability standards — ensuring they are ready for the road, the grid, and the customer.

Table of Contents

Why EV Charger Testing Matters

The EV charging ecosystem is complex. Chargers — both external (AC/DC) and on-board — must not only deliver power safely and efficiently but also communicate seamlessly with vehicles, payment systems, and grid infrastructure. Key challenges include:

- Safety Compliance: Avoiding hazards like overheating, short circuits, or electrical surges.

- Interoperability: Ensuring compatibility across different EV makes, models, and charging standards.

- Durability: Withstanding harsh outdoor environments, from high heat to monsoon rain.

- User Experience: Guaranteeing smooth plug-in, charging, and disconnect processes without glitches.

A robust testing strategy addresses these factors early in the product lifecycle, reducing costly recalls and market delays.

VVDN’s EV Charger Testing Capabilities

Our dedicated EV charger testing services cover AC and DC chargers of varying capacities, from residential 3.3kW units to high-power public fast chargers, as well as OBC systems integrated within vehicles.

1. Electrical & Functional Validation

- Load testing across different charging profiles.

- Overvoltage, overcurrent, and fault condition simulation.

- Efficiency and power factor measurements.

2. Communication Protocol Testing

- Validation of CCS, CHAdeMO, GB/T, and OCPP protocols.

- ISO 15118 Plug & Charge feature testing.

- End-to-end EV–charger handshake and interoperability verification.

3. Environmental & Reliability Testing

- Thermal cycling and extreme temperature operation.

- IP-rated water and dust ingress testing.

- Vibration and mechanical shock endurance.

4. Safety & Compliance Testing

- Adherence to IEC 61851, UL, BIS, and other international standards.

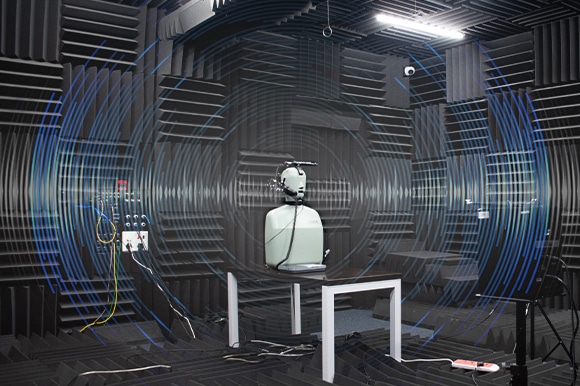

- EMC/EMI testing for regulatory approval.

Serving Every Segment in the EV Value Chain

We work with:

- Automotive OEMs – To integrate and validate charging solutions, including OBCs, directly with vehicle platforms.

- Aftermarket Brands – To ensure universal compatibility for chargers targeting diverse EV markets.

- EV Infrastructure Providers – To simulate real-world field conditions before large-scale deployment.

Why Partner with VVDN for Charger Testing

- End-to-End Support: From prototype validation to certification readiness.

- Custom Test Bench Design: Tailored setups for unique product specifications.

- Multi-Disciplinary Expertise: Hardware, software, and mechanical validation under one roof.

- Global Reach: Testing aligned to market-specific compliance requirements.

Driving Your Charging Innovation Forward

Whether you are launching a new EV charger, upgrading an existing product line, or validating on-board charger integration, VVDN offers the expertise, infrastructure, and fast turnaround needed to take your charging solution from concept to certified, market-ready product.

Have a project in mind? Reach out to our experts to discuss your EV charging validation requirements and explore how we can support your next launch.